The Confusing World of Adjuvants

The Confusing World of Adjuvants

By: Tommy Butts, Extension Weed Scientist

Adjuvants perform numerous roles within a spray application and there are a wide variety of different options available. Some adjuvants work by reducing surface tension of the spray solution resulting in fewer droplets that bounce and shatter (spreaders/stickers; surfactants) and some help improve spray water quality by tying up cations associated with hard water (water conditioners). Others break down the leaf cuticle to enhance absorption (oils) and some increase droplet size to reduce drift potential (drift reduction adjuvants). As a result, there are no “one size, fits all” type adjuvants that can be or should be used for every application.

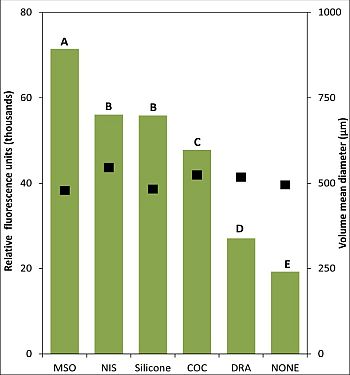

Research results have shown that a herbicide solution with methylated seed oil (MSO) had the greatest retention on a plant surface compared with other tested adjuvants (Figure 1) (Creech 2015). Nonionic surfactant (NIS), silicone, and crop oil concentrate (COC) adjuvants also increased retention of a herbicide solution on a plant surface compared to a drift reduction adjuvant (DRA) and no adjuvant; however, it was to a lesser extent than the MSO. This may help explain increased weed control observed when MSO, NIS, silicone, and COC adjuvants are used, but it can also explain the added crop injury potential especially with certain MSO products. Recommendations on herbicide labels should be followed to maximize the effectiveness of the herbicide while not substantially increasing crop injury.

Other research has shown the effect of adding a water conditioning adjuvant like AMS

to herbicide solutions for increased weed control, especially in hard water environments.

In a greenhouse study conducted recently here in Arkansas (Figure 2), Roundup PowerMax

alone at 11 fl oz/acre provided approximately 65% control and Roundup PowerMax plus

added NIS (0.25% v/v) provided approximately 75% control of a barnyardgrass population.

When AMS (2 lb/acre) was used, nearly 100% control was achieved with the same rate

of Roundup PowerMax.

Adjuvant labels should also be carefully read prior to use to identify the actual type of adjuvant it is and to follow the manufacturer recommended rates. I have received reports of high surfactant oil products (HSOC) such as Superb HC being recommended at standard COC rates (1% v/v). This will lead to much greater crop injury potential. An HSOC and COC are not equivalent adjuvant types as an HSOC contains a much greater load of surfactant. The recommended rate for an HSOC like Superb HC is half a normal COC rate (0.5% v/v).

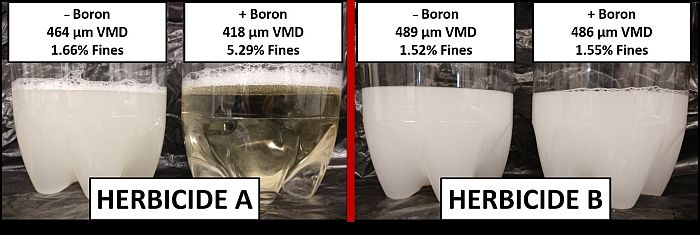

Anytime a new herbicide solution or adjuvant combination is to be used, consultants or applicators should perform a jar test to test for compatibility and applicators should carefully observe the application for drift potential and efficacy. Figure 3 and Figure 4 illustrate a couple of examples of severe incompatibility when adjuvant or micronutrient products were added to herbicide solutions. In Figure 3, the addition of a DRA caused some WDG formulated herbicides to precipitate out and never fully go into solution. Not only could this lead to plugged sprayer equipment, a majority of the herbicide activity has been lost. In Figure 4, when the micronutrient boron was added to herbicide solution A (left panel), you can see a drastic change in the chemical solution. When those spray solutions were evaluated for droplet size, the solution with boron had a decreased droplet size and almost four percentage points more driftable fines when sprayed through a TTI nozzle. In contrast, when boron was added to herbicide B (right panel), no observable effect to the herbicide solution occurred and droplet size remained relatively unchanged.

Care should be taken to read each herbicide label and follow the recommendations provided on adjuvant selection. If tank-mixing herbicides, the first option would be to select an adjuvant that is recommended on both labels. If no overlap of recommended adjuvants occurs, typically a NIS or COC are the most viable options to use to increase activity while limiting crop response. Use best judgment as well with certain herbicides on whether an additional adjuvant is even needed. Often, a tank-mixture with heavy surfactant loaded products (such as Roundup PowerMax II) does not require the addition of another adjuvant.

If any questions arise or if I can help at all, please don’t hesitate to get a hold of me at tbutts@uada.edu or (501) 804-7314. Good luck out there.

References:

Creech CF (2015) Herbicide Application Technology Impacts on Herbicide Spray Characteristics and Performance. Lincoln, NE: University of Nebraska-Lincoln. 205 p