Contact

Agriculture and Natural Resources

On-Farm Grain Sorghum Drying and Storage

In Arkansas, grain sorghum does not typically field-dry to a safe moisture content (MC) to avoid quality losses (12% wet basis). Therefore, it must typically undergo artificial drying to achieve the target MC for safe storage. Grain sorghum has its highest quality at harvest and subsequent post-harvest handling and processing must be carefully planned and managed to avoid a decrease in quality and market value, and provide Arkansas producers with a measure of control over the quality and market value of their grain sorghum.

Grain sorghum is dried by forcing large quantities of unheated or heated air though the grain bulk. Air temperature and relative humidity (RH) are the two key characteristics that determine the drying rate and the final MC of the grain. For any specific air temperature and relative humidity, grain sorghum will only dry until equilibrium is reached between the moisture in the grain and the moisture in the air. The moisture content of the grain at this equilibrium point with air at a specific temperature and relative humidity is called "Equilibrium Moisture Content” (EMC).

Table 1 shows EMC of grain sorghum in equilibrium with air at various temperatures and relative humidity levels. As an illustrative example, if the grain sorghum is dried with air at a temperature of 60oF and RH of 70%, then EMC is 14.1%. Therefore if the grain sorghum is placed into the drying bin at a MC of 18%, and it is dried with air at 60oF and 70% RH, the grain sorghum will dry until it reaches a MC of 14.1% and will remain at this MC as long as the air stays at a temperature of 60oF and RH of 70%. Note that if the air is heated, not only will the temperature increase, but the RH will decrease. From Table 1, if the air is heated, EMC will decrease. Thus, temperature and relative humidity properties of the drying air determine the sorghum moisture level during drying and storage. The EMC may be determined by measuring air temperature and relative humidity and using Table 1.

A sling psychrometer is one of the tools used for measuring relative humidity, and is relatively inexpensive. A sling psychrometer works by measuring the air temperature with a wet and dry bulb thermometer, and then using a table to determine relative humidity. EMC of drying air also affects the rate that the grain sorghum is dried. The difference between the EMC of the air and the actual MC of the grain is proportional to the drying rate. Therefore, wet grain sorghum at 18% MC from the prior example exposed to 60 °F, 70% RH air with an EMC of 14.1% will dry more slowly than if the grain sorghum was exposed to 70 °F, 50% RH air with an EMC of 11.4%. Accordingly, grain sorghum may be dried without adding any heat to the drying air if the EMC is sufficiently low compared to grain moisture content.

Careful monitoring of the EMC of the drying air and management of air flow rates and drying operations is necessary to take advantage of weather periods when EMC is low will provide the most economical drying. In many cases, particularly at night and during high humidity weather patterns, the addition of heat is needed to lower the EMC of the drying air. To determine the value of EMC in your area now, click the link Determination of the current temperature and relative humidity based on your zip code.

Table 1: EMC of grain sorghum in equilibrium with air at various temperatures and

relative humidity levels

|

Relative Humidity (%) |

||||||||

|

Temperature (oF) |

30 |

40 |

50 |

60 |

70 |

80 |

90 |

|

|

40 |

9.6 |

10.8 |

11.9 |

13.1 |

14.5 |

16.1 |

18.4 |

|

|

50 |

9.4 |

10.6 |

11.7 |

12.9 |

14.3 |

15.9 |

18.2 |

|

|

60 |

9.2 |

10.4 |

11.5 |

12.7 |

14.1 |

15.7 |

18.0 |

|

|

70 |

9.0 |

10.2 |

11.4 |

12.6 |

13.9 |

15.5 |

17.8 |

|

|

80 |

8.9 |

10.1 |

11.2 |

12.4 |

13.7 |

15.3 |

17.6 |

|

|

90 |

8.7 |

9.9 |

11.0 |

12.2 |

13.5 |

15.1 |

17.4 |

|

|

120 |

8.6 |

9.8 |

10.9 |

12.1 |

13.4 |

14.9 |

17.2 |

|

To learn more about Equilibrium Moisture Content, see the fact sheet titled: "Grain Drying Tools: Equilibrium Moisture Content Tables and Psychrometric Charts"

To determine the values of EMC for various grains, download the Excel sheet by clicking the link: "Equilibrium Moisture Content"

One way to cause the grain to reach equilibrium with the air sooner and therefore

dry faster is to increase the flow rate of air over the grain. For most typical in-bin

grain drying systems, drying time is cut in half if the airflow rate is doubled.

The airflow rate needed to dry grain sorghum depends on the initial moisture content

of the grain. Airflow rates for drying vary from 0.5 cfm/bushel to more than 50 cfm/bushel

for commercial or batch dryers. Most on-farm airflow rates for drying vary from 0.5

to 6 cfm/bushel dependent on the initial moisture content of the grain and the amount

of heat added to the drying air. Table 2 shows the minimum recommended airflow rate

to dry sorghum at various levels of initial grain moisture content.

Table 2: Recommended Minimum Airflow Rates for Drying Grain Sorghum

|

Initial Moisture Content (%) |

Airflow Rate (cfm per bushel) |

|

11% to 13% |

0.5 |

|

13% to 15% |

1.0 cfm/bu |

|

15% to 18% |

2.0 cfm/bu |

|

18% to 20% |

3.0 cfm/bu |

|

20% to 22% |

4.0 cfm/bu |

|

>22.0% |

6.0 cfm/bu |

To select and maintain your fan, please see the fact sheet titled "Selection, Performance and Maintenance of Grain Bin Fans"

-

Sorghum grains contain moisture and dry matter. The actual value of the sorghum is contained in the dry matter so adding or removing moisture alone should not affect the price. This is why a base moisture content of 14.0% wet basis is typically used to calculate price for sorghum at the elevator. Variations of sorghum moisture content change its weight per bushel as shown in Table 3 and this is used to determine dockage for overly wet grain.

Table 3: Sorghum Weights corresponding to One Bushel at Market Standard Moisture Content

Moisture Content (%)

Weight

(lb/bu)

Moisture Content (%)

Weight

(lb/bu)

Moisture Content (%)

Weight

(lb/bu)

30.0

67.57

23.0

61.43

16.0

56.31

29.0

66.62

22.0

60.64

15.0

55.65

28.0

65.69

21.0

59.87

14.0

55.00

27.0

64.79

20.0

59.13

13.0

54.37

26.0

63.92

19.0

58.40

12.0

53.75

25.0

63.07

18.0

57.68

11.0

53.15

24.0

62.24

17.0

56.99

10.0

52.56

The above conversion contains the weight of sorghum at various moisture levels. Here is an example to illustrate how these values were calculated.

How many pounds of 18.0% moisture sorghum is equivalent to a standard bushel?

The percentage of dry matter in a standard bushel (14.0% MC) = 100.0-14.0 = 86.0%.

The percentage of dry matter in one bushel of sorghum at 18.0% MC = 100.0-18.0 = 82.0%.

The shrinkage weight corresponding to one bushel at 18.0% MC = (86.0 ÷ 82.0) × 100 = 104.87%.

The shrinkage weight corresponding to one bushel at 18.0% MC = 104.87 × (55.00 lb) ÷ 100 = 57.68 pounds equivalent to a standard bushel.

It should be noted that if sorghum is delivered to the elevator at a moisture content above the base level of 14.0 %, buyers apply “shrink factor” to adjust the quantity for the excess moisture so the dry matter purchased is equivalent to base moisture content sorghum. Applying the shrink factor approximates the equivalent number of bushels that would be in the load if sorghum were dried to the base moisture content. Typically, buyers may be using slightly higher shrink factors than calculated here in order to account for handling losses during drying. Conversely, it should also be noted that if farmers deliver sorghum with moisture level less than base moisture, there is no added compensation to account for the additional dry matter contained in the over dry bushel. Therefore, it is critical to avoid over drying grain.

-

In-Bin Drying

Natural air-drying and low temperature drying typically occur in bins with one or more fans attached to the bin. The fans may also be attached to a heater for low temperature drying. Natural air-drying does not utilize a heater. Natural air or slightly heated air (<10°F) is forced up through the grain with fans for a sufficient time to reduce grain moisture content to safe storage levels. This is typically done in bins with a perforated floor to ensure even airflow, but can also be done using air ducts laid on the bin floor prior to adding grain. Grain sorghum offers higher resistance to airflow than corn or soybeans. Thus, bin-drying methods used for other grains can be adapted to grain sorghum if some adjustments are made to compensate for the high resistance to airflow. The simplest way is to reduce grain sorghum depth in the bin to half that is used for corn or soybean. In addition, the installation of centrifugal fans may help to deliver higher airflow rates under higher static pressures.

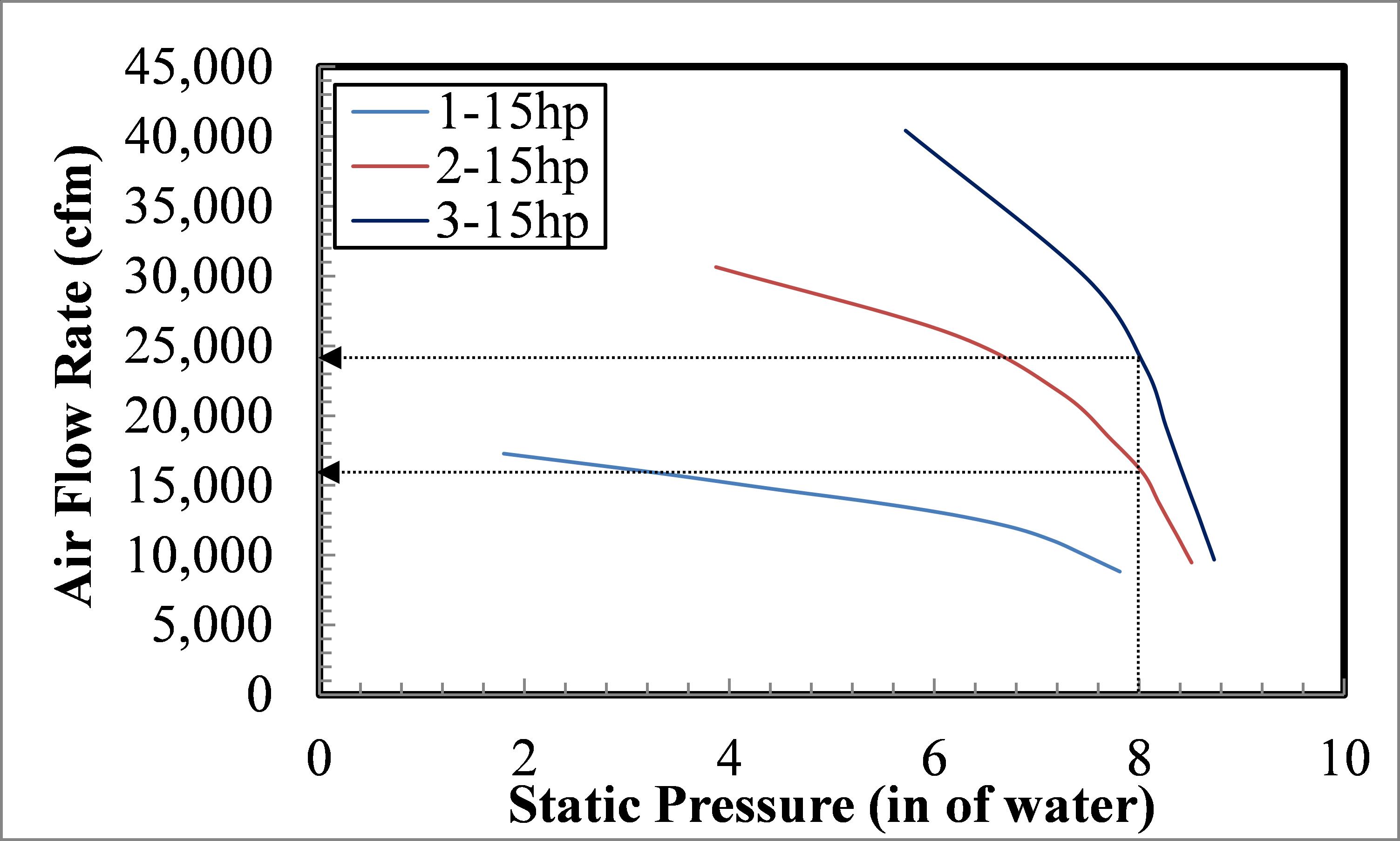

Bin capacity, as measured in bushels of grain, increases by increasing the bin diameter and/or the grain depth as shown in Table 4. A grain bin with 28 ft diameter and 16 ft height can hold up to 7,882 bushels of grain sorghum. Increasing the grain depth increases the static pressure that the fan must overcome to provide the required airflow rate. See Figure 6 for a graphical representation of the relationship between fan size, airflow rate, and static pressure requirement.

The following is an illustrative example of how to use the information presented to this point for estimating the fan requirements for drying grain sorghum. A 30-foot diameter bin is filled to a depth of 8 feet with grain sorghum at a moisture content of 18% wet basis that must be dried. Table 2 recommends a minimum airflow rate of 3 cfm/bu for 18% MC grain sorghum. Table 5 shows that the capacity of the bin at this depth is 4,524 bushels. Therefore, the total airflow rate required from the fans in cfm is 3 cfm/bu * 4,524 bu = 13,572 cfm. Table 4 shows that the static pressure requirement for 8 ft. depth at 3 cfm/bu = 5.11 in water. Figure 5 shows that 1-15 hp fan will provide about 15,000 cfm to the grain sorghum, which exceeds the 3 cfm/bu (13,572 cfm) requirement. Therefore, 1-15 hp fan will provide the proper airflow required to dry grain sorghum with an initial moisture content of 18% wb in the 30 ft. bin filled to a depth of 8 ft. It should be mentioned that for a 30-ft or 32-ft bin, grain sorghum depths greater than 20 feet would generally reduce airflow rates to less than 1 cfm /bu even with the use of 3-15 fans. Accordingly, Table 6 could be used to simplify the selection of grain depth as a function of grain sorghum MC and fan size.

If high moisture grain sorghum is to be dried and stored in the same bin, extra care is advised. Stirring devices, re-circulators, or automatic unloading augers can be used to increase the drying rate. For high moisture content grain sorghum, it is recommended that after drying grain sorghum to 17%, use unheated air to dry it to about 15%. During this period, run the fan continuously to maintain uniform moisture content. Once the grain sorghum has dried to 15%, run the fans only during low humidity hours to finish drying to around 13%. This management scheme will minimize the amount of grain sorghum overdrying in the bottom of the bin. Never use air heated above recommended temperatures as this can cause severe overdrying resulting not only in wasted energy that is uncompensated at the elevator buying point, but also damage quality of the grain sorghum.

Table 4: Number of Grain Sorghum Bushels in Grain Bins

|

Grain depth (ft) |

Bin Diameter (ft) |

||||||

|

20 |

22 |

24 |

26 |

28 |

30 |

32 |

|

|

2 |

503 |

608 |

724 |

849 |

985 |

1,131 |

1,287 |

|

4 |

1,005 |

1,216 |

1,448 |

1,699 |

1,970 |

2,262 |

2,574 |

|

6 |

1,508 |

1,825 |

2,171 |

2,548 |

2,956 |

3,393 |

3,860 |

|

8 |

2,011 |

2,433 |

2,895 |

3,398 |

3,941 |

4,524 |

5,147 |

|

10 |

2,513 |

3,041 |

3,619 |

4,247 |

4,926 |

5,655 |

6,434 |

|

12 |

3,016 |

3,649 |

4,343 |

5,097 |

5,911 |

6,786 |

7,721 |

|

14 |

3,519 |

4,257 |

5,067 |

5,946 |

6,896 |

7,917 |

9,008 |

|

16 |

4,021 |

4,866 |

5,791 |

6,796 |

7,882 |

9,048 |

10,294 |

|

18 |

4,524 |

5,474 |

6,514 |

7,645 |

8,867 |

10,179 |

11,581 |

|

20 |

5,027 |

6,082 |

7,238 |

8,495 |

9,852 |

11,310 |

12,868 |

Figure 5: Graphical representation of the relationship between fan size, airflow rate, and static pressure requirement. Single and multiples fans static pressure and airflow rate.

Table 6: Maximum Safe Drying Depth for Grain Sorghum with Typical Bin and Fan Combinations.

|

Bin diameter |

Fan Horsepower |

Moisture content of grain placed in the bin |

|||

|

11-13% |

14-15% |

16-17% |

18-20% |

||

|

Safe Depth of grain – ft |

|||||

|

18 |

5 |

20 |

16-18 |

10-12 |

6-8 |

|

21 |

7.5 |

||||

|

24 |

10 |

||||

|

27 |

10 |

||||

|

30 |

15 |

||||

|

33 |

20 |

||||

- Batch and Continuous Flow Drying

High temperature batch or continuous flow dryers are usually used to dry large capacities of grain sorghum. These units typically have very high airflow rates, and they do not require supplemental heat for daytime drying when harvesting grain sorghum at 18-20% moisture range. If heat is used, the drying air temperature can be limited by cycling the burner on and off or by changing the gas burner orifice size using an automatic modulating valve.

Example of on-farm grain drying and storage facility

Pass or continuous flow dryers are often utilized to speed up the drying process. These high flow driers pass very large amounts of high temperature air over the grain sorghum. Three to six moisture percentage points may be removed from the grain in a single pass. The grain exiting these types of dryers must be cooled to near ambient temperature prior to storage or transport. Continuous flow drying helps to rapidly prepare grain for shipment to market if needed. Quickly drying the grain down to values of 16% or less will lessen potential spread of toxins for affected grain.

- Pros and Cons of On-Farm Grain Sorghum Drying

Grain sorghum growers who use on-farm grain sorghum drying and storage list numerous advantages of these technologies. On-farm drying and storage costs may be less than the drying price reduction at a commercial dryer, particularly if some other crop may justify the capital cost of their on-farm equipment. For comparison to reductions at a commercial dryer, on-farm energy costs for electricity and liquid propane range from 3 to 4 cents per bushel per point of moisture removed. In addition, on-farm drying may make it economically feasible to harvest grain sorghum early, at moisture content higher than the dockage level at a commercial dryer. This provides the grower with more flexibility for managing their business. Additionally, early harvest and proper drying can produce better quality grain sorghum compared to grain sorghum that is re-wetted in the field several times while field drying to a dockage level.

Following are some tips that may help grain sorghum producers achieve better grain quality while minimizing the drying cost:

- Harvest grain sorghum at 20% or less moisture content. Grain sorghum requires extra care for harvesting above 20% moisture, so this is the practical upper limit for drying. Adjust the combine to minimize the amount of trash collected with the grain.

- Load grain into clean bins immediately after harvest. Bins should be cleaned and sanitized prior to harvest to minimize insect problems. Move grain sorghum from the field to grain bins as soon as possible. The amount of time before spoilage begins depends on grain moisture content and air temperature. A safe rule of thumb is to hold freshly harvested grain sorghum in carts or trucks no longer than 12 hours. Warm air temperatures > 80oF, and higher grain moisture levels are the most critical factors determining grain spoilage.

- Check the moisture content of each load of grain as it is placed in the drying bin. There can be some variation in moisture content throughout the field, but you need to know the average of the bin to determine the minimum necessary airflow needed and the allowable depth of grain in the bin.

- Open air exits and start the fan. As soon as the grain depth is about 1 foot deep on the perforated floor, open the air exit and start the fan. This will help control the moisture content in the grain and prevent spoilage issues from emerging.

- Add grain sorghum to drying bin in shallow layers until the moisture content decreased. High moisture grain sorghum (18 to 20%) can be added in 4-foot layers on top of dry grain if the fan can provide at least 3 to 4 cfm/bu through the total depth in the bin. As an example, 6 feet of 20% moisture grain sorghum can be dried to 14.5%, then 4 more feet of 18 to 20% moisture can be placed on top of that. The fan must be capable of working against the static pressure developed by 10 feet of grain to provide at least 4 cfm/bu for the additional 4 feet of wet grain.

- Level grain sorghum inside each drying bin continuously and never allow coning to occur. Be sure to use spreading devices or some other means to keep the grain leveled as the bin is being filled. This will ensure uniform airflow through all the grain assuming it has been placed in the bin with a good spreader. If the grain is allowed to cone, there will be an increase of small particles in the center core and increases the static pressure requirement to move air through the center core. This increased pressure requirement will allow air to short circuit the center core. This makes it very difficult to dry and control moisture uniformly in the grain bin.

- Use stirring devices when drying grain sorghum if possible. If stirring devices are used, the temperature can be set as high as 130oF (except 105oF maximum for seed grain sorghum). Stir augers will blend the grain sorghum sufficiently to prevent it from drastically over-drying near the bottom of the bin as well as prevent excessive grain temperatures that can reduce quality

- Monitor the moisture content of grain sorghum daily. Grain sorghum must be cooled to avoid nighttime condensation on the inner walls and subsequent rewetting of the grain. If the heater has been on long enough for the complete mass of grain sorghum to be warmed and the weather is clear and dry with humidity below 60%, turn the heater off when the moisture content of the grain drops to within 1% of the target moisture content. Continue running the fans, and the residual heat in the grain will finish the drying process.

- Aerate with natural air once the grain is below 13% moisture content. Once dry, grain sorghum being stored should be kept to a temperature within 10 degrees F of the outside air temperature to prevent moisture migration that can result in grain wetting and spoilage. Cooling air should be checked for humidity, being careful to aerate when humidity is below about 60% or better yet when the EMC content is at or below the target moisture level. Avoid aeration with high humidity air since it will add moisture back to the grain. Airflow rates required for aeration are typically much lower than required for drying.

- Probe the bin periodically to check for insect infestation and grain temperature increase. Grain temperature increase usually means moisture migration. Aerate proactively to prevent this problem, and whenever moisture migration is detected. If the problem is in the center of the bin and aeration is not effective, move the grain to another bin to solve this problem. Problems in the center of the bin usually indicate that a lot of fines and/or trash accumulated in this area during filling. Activation of stirring devices, if available, can also solve this problem.

Never add more heat than necessary to adjust the humidity of the drying air below 55%. The maximum heat needed, even in rain or 100% humidity will be about 15-17oF above the outdoor temperature. Adding too much heat can over-dry the bottom layers of grain to as low as 8% and that reduce the market weight. Recommendations for heated air temperature rise are to: add 15 degrees F if the outside air humidity ranges between 85 to 100%; add 10 degrees F for 75 to 85% humidity and 5 degrees F for 55 to 75% humidity. If the humidity is 55% or less, use natural air for drying.

-

During long-term storage, grain sorghum quality is affected by several factors including moisture content, temperature, and insect infestation, which if not properly controlled can shorten the safe storage period. Grain sorghum shares these factors with all other grains. Sorghum cleanliness, however, is another factor that might affect air movement within the grain bin during storage and reduce the risk of spoilage. The following are some tips that may help sorghum producers to achieve better grain quality during storage:

- Clean the area around the bin. As much as possible, keep the area around the bin clean. This area should be free from tall grass and spilled grain as this environment attracts birds and rodents. Additionally, seal all areas around the bottom of the bins and keep transfer equipment sealed to prevent rodents from migrating into the system.

- Remove previously stored grain from the bin before filling it with new grain. Thoroughly sweep the bin wall and floor to remove the remaining kernels that may contain insect larvae and mold spores. Apply a recommended insecticide both inside and outside the bin to delay insect population development before placing grain sorghum in the bin.

- Adopt sanitation to avoid spoilage. All equipment involving grain transportation and handling should be cleaned and inspected on regular basis to protect the new crop from any infested remains of old grain from the machinery.

- Clean trash from grain. It is crucial to place clean sorghum in the storage bin. Set harvesting equipment to produce a minimum of trash in the grain prior to drying. Once dry, if grain cleaning is not economically feasible; fill the grain bins by using spreaders. This prevents the trash from concentrating in the central core of the bin.

- Monitor stored grain regularly and aerate regularly. Stored grain should be monitored frequently to observe any identifiable spoilage early so action can be taken to prevent the loss of large sections of stored grain. Temperature sensors can be installed at various locations within the bin to monitor temperature on a continuous basis. These sensors are particularly good for monitoring those areas where hand held sensors cannot reach. Aerate grain often to maintain uniform temperature and moisture levels and prevent large temperature differences between that of the stored grain and outside air

- Cool grain sorghum to 40°F if possible. Apply aeration to cool sorghum after being dried with heated air. Aeration will control grain temperature, remove any heating occurring during storage, and avoid further damage to grain quality. If aeration cannot control hot spots, move grain sorghum to another bin to break up these hot spots.

- Monitor the top 6 to 12 inches of grain sorghum. Monitor temperatures and insect/mold activity. Insert plastic insect traps below the grain surface to monitor insect activity and check them during weekly inspections to control damaging populations. Make sure to secure these traps to a fixed structural member of the bin.

- Cover fans and openings when not in use. This will prevent air, moisture, and potential insect movement. Monitor carefully and fumigate if needed. Check grain and manually inspect it with your arm or a rod, smelling, feeling and looking for indications of trouble. Evidence of hot spots, warming, insect infestations or other problems that start in the grain mass can soon migrate to the surface. Be particularly sensitive to damp, warm, or musty areas.

- Mix the upper and lower portions of grain in the bin using stirring equipment. This speeds up the drying process and loosens the grain, so that additional air may be moved up through the grain. Stirring equipment also helps to keep the grain leveled in the bin. Stirring equipment should not be turned on unless the bottom end of the down auger is at least 1 foot deep in grain. They can run almost continuously after that point, when the drying fans are running.

- Do not allow grain to cone or pile to one side as the bin. If coning or sloping occurs, the large particles will migrate to the outside and the small particles and trash will remain at the center of the cone. This results in a non-uniform amount of air being passed through each portion of the grain. Most of the air will pass up the outside of the bin through the larger and cleaner grain. Allowing a large amount of grain to pile on one side of the bin can also cause structural damage to the bin, which is typically designed to support a uniform load provided by level grain.

- Do not mix dry and wet sorghum. Care should be taken not to mix dry grain (moisture content < 15%) with moist grain (moisture content > 18%). The wet grain can create hot spots and re-wetting may also occur as air removes moisture from the wet grain and deposits it into the dry grain.

It is essential to maintain the on-farm grain sorghum drying cost at a minimum in order to maximize the return on investment. To estimate drying costs for producers interested in drying their grain sorghum need to first determine the total pounds of water they will remove from one bushel of grain. The number of BTUs to extract 1 pound of water will vary from 1,100 to 1,400 BTU/pound depending on how easily moisture is given up by the kernel. A good estimate is to use an average of 1,200 BTU/pound of water removed to calculate the energy needed to get rid of 1 pound of moisture. Table 7 summarizes the BTU/unit of fuel as well as the burning efficiencies. Burning efficiencies estimate the conversion of raw gas use to energy. Therefore, if one gallon of LP gas is consumed by the heater with a burning efficiency of 80%, then the amount of heat added to the air is 0.8*92,000 = 73,600 BTUs.

Table 7: Heating value of fuel as well as their corresponding efficiencies

|

Fuel |

BTU |

Unit |

Burning efficiency |

|

LP gas |

92,000 |

Gallon |

80% |

|

Natural gas |

1,000 |

Ft3 |

80% |

|

Electricity |

3,413 |

kWh |

100% |

Total grain sorghum drying costs may be estimated using the following equation(s):

Fan motor cost:

Fan motor cost ($/h) = fan HP x 0.7475 (kW/HP) x electricity cost ($/kWh)

Fuel cost:

Fuel cost ($/bu) = [BTU/lb water x (lb water removed/bu) x fuel cost ($/unit of fuel) x 100] /

[(BTU/unit of fuel x burning efficiency %]

Grain sorghum drying cost ($/bu) = fan cost ($/h) x drying time (h/bu) + fuel cost ($/bu)

Working with either moving and/or stationary grain requires special precautions and training. Therefore, it is necessary to keep in mind the following tips while working with grain sorghum as well as other grain:

- Do not inspect grain bin alone. Always request help from coworkers when entering a bin. Inspection requires at least one worker inside the bin with a safety harness and one outside to assist if needed. When entering a questionable bin, ask two workers to stay outside for assistance if needed. A safety rope should be attached to the worker who is entering the bin. The workers standing outside must be capable of pulling the person inside if an emergency arises.

- Do not enter into a grain bin or gravity unloading vehicle when grain is flowing. Several accidental deaths occur yearly during handling and unloading grain. Therefore, lock out the control circuit on automatic unloading equipment before entering or cleaning a bin or repairing conveyors. Flag the switch on manual equipment so someone else does not start it. Do not enter a bin unless you know the nature of previous grain removal, especially if any crusting is evident that may indicate very dangerous bridging.

- Avoid walking on any surface crust. Crusted or bridged grain can collapse and could bury and suffocate workers. Do not depend on a second person on the bin roof, on the ground, or at some remote point to start or stop equipment on your shouted instructions. If a grain bin is peaked close to the roof, be extremely cautious. Crawling between roof and peak can cave grain and block the exit.

- Wear appropriate masks when working around dust. Always wear a respirator mask capable of filtering fine dust to work in obviously dusty or moldy grain. Never work in such conditions, even with protection, without a second person on safety standby. Exposure to and inhaling mold can cause severe allergic reactions.

- Be alert while working with out of condition grain. Grain that has gone out of condition may contain molds, cavities, cave-ins, or crusting.

- Exercise caution while working with flowing grain. Flowing grain can trap and suffocate a worker in seconds. Moreover, the noise coming out of the equipment further blocks the shouts for help. Even with moderate flow rates of a 6" auger, a worker is trapped only 2-4 seconds after stepping into the cone of flowing grain. This worker would be totally submerged within 20 seconds at a grain flow rate of 1,000 bu/h.

- Electrocution from grain augers. Grain augurs are usually as long as 40 to 50 feet, and are used to place grains in bins. Sometime while moving the auger from one bin to other, there is a chance that the upper end of it touches overhead power cable. Caution should be exercised while maneuvering the grain augers. Or, in the first place consider installing underground power cables or make an arrangement to move the wires too close to metal bins.