Grain Handling Safety

Flowing grain remains the number one cause of fatalities for grain handlers. Large or unstable quantities of grain can flow like liquids. Unlike water, which allows a person to swim, it is difficult or impossible for a grain handler to move if caught in grain flow. A grain handler can be buried in a few seconds if caught in grain flow, resulting in suffocation.

- The number of agricultural confined-space incidents in the United States between 2012 and 2015 totaled 114 cases, as reported by a Purdue University database (See the Table below). Unfortunately, the ratio of the fatal cases to the total ranged between 39.4 and 58.3 percent. The majority of these cases were related to entrapment or engulfment in free-flowing grain. Other cases were related to machinery entanglement inside grain storage facilities or from asphyxiation due to toxic atmosphere in partially closed storage structures.

- Flowing grain and entanglement are the top causes of fatalities in grain handling facilities. Entanglement from moving fans, blades, augers,power takeoffs (PTOs), belts, gears and pulleys can severely injure, disfigure and cause limb amputation or death to workers.

- The entire body of a 6-foot-tall person can be completely engulfed within grain in

about 30 seconds. Without immediate rescue, this

person will suffocate.

The number of nonfatal and fatal incidents related to grain entrapment in the United States

|

Year |

2012 |

2013 |

2014 |

2015 |

|---|---|---|---|---|

|

Nonfatal |

11 |

20 |

21 |

10 |

|

Fatal |

8 |

13 |

17 |

14 |

|

Total |

19 |

33 |

38 |

24 |

|

Fatal/Total |

42.1% |

39.4% |

44.7% |

58.3% |

Grain Bin Entrapment and Engulfment

The term entrapment implies an incident when a grain bin worker becomes buried in

the grain beyond the point of self-extraction. On the other hand, the term engulfment

implies an incident when a grain bin worker is completely buried or submerged beneath the

surface of the grain. In many cases, grain entrapment leads to engulfment which, in

turn, is fatal.

Causes of Grain Bin Entrapment

According to the Occupational Safety and Health Administration (OSHA), most incidents

of entrapment suffered by grain handlers who have entered bins or silos resulted when:

- Grain handlers did not follow proper safety procedures.

- Grain handlers were without personal protective equipment.

- Grain handlers entered bins or silos while grain was flowing and equipment was running and were sucked under the grain. If a grain-probe or shovel is dropped in grain bin, the flow of grain should stop first before taking any action to retrieve the lost item.

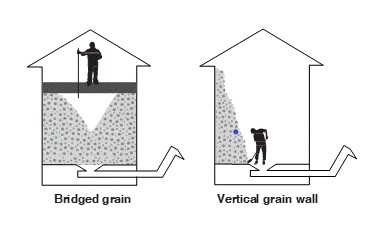

- Grain handlers fell through bridged grain into an air pocket that was formed beneath spoiled grain.

- Grain handlers tried to break a vertical grain wall.

Tips to Help Avoid the Danger of Grain Entrapment and Engulfment

Entrapment and engulfment incidents in grain bins are avoidable. The best prevention

for grain engulfment is to avoid entering the grain bin.

However, flowing grain incidents may also occur when loading and unloading trucks

and bins, when surface crusts collapse and when steep or vertical grain piles collapse.

A fact sheet available from your county Extension office, Grain Bin Entrapment and Engulfment Causes, Prevention and Rescue, has additional suggestions related to grain bin handling safety. Following are a

few tips that might help producers avoid the danger of grain entrapment and engulfment:

- Grain handlers should take into account all preventative safety measures including proper ladders, scaffolds, etc.

- Grain handlers should be able to use prearranged arm and hand signals due to difficulty hearing when grain handling or drying equipment is operating nearby.

- Grain handlers trying to rescue one victim should not endanger another person.

- Grain handlers should prepare appropriate breathing apparatus if the victim has been unable to get sufficient oxygen or has been breathing air containing grain toxins.

Grain Bin Entrapment Rescue Technique

Remember, entrapped persons need immediate help. It is much easier to help and successfully

rescue the trapped person if you have an accident response plan. The trapped person

should contact the helper waiting outside the bin immediately. It should be mentioned

that pulling a trapped person from grain could be very difficult due to the friction

forces transferred from the grain to the trapped person’s body.

Therefore, it is not advisable to winch a person from grain if the person is buried

deeper than knee deep. This may cause joint dislocation, paralysis and other severe

injuries. The grain must be removed from around the person to get him/her out. This

can be done by creating a cofferdam around the person and bailing out grain with a

vacuum or bucket. Grain cofferdams can be constructed by driving sheets of plywood

around the person. They can also be constructed using plastic barrels. Currently,

there are several commercially available grain rescue tubes. These tubes have linking

pieces that are connected and driven into the grain to create a cofferdam. Commercial

rescue tubes typically have steps on the inside to assist the victim in climbing out

of the grain.

Confined Space Entry

Even a small amount of spoiled grain can produce millions of tiny mold spores, which

easily become airborne when disturbed. Airborne mold spores can be inhaled through

the nose and mouth, irritating sensitive lung tissue and, in some individuals, causing reactions

so severe that hospitalization is necessary.

Farmers working without respiratory protection inside a bin or other grain storage facility in which moldy grain is present are especially vulnerable to mold reactions. When handling any grain where mold damage is present, the use of an appropriate respirator is essential. This applies even to truckers, scale operators and those supervising the dumping operations at an elevator.

After exposure to high concentrations of mold spores, it is important to change clothing (or use disposable overalls) to avoid bringing the mold spores home and exposing family members. If you do become ill after exposure to moldy grain, consult a physician and make him or her aware of your activities. Medical attention may be necessary in some cases.

Storage and handling of large volumes of grain or feed on farms is common in many areas. Automated equipment has made handling of grain easy and fast. But, grain storage structures and handling equipment create hazardous work areas. Farm workers should make sure they take the proper steps to put safety first to prevent injuries, illnesses and even death.

Grain bin suffocation accidents,from entrapment or engulfment, are reminders that grain storage, especially flowing grain, may become very dangerous. This fact sheet discusses crucial information related to grain entrapment and engulfment with extra focus on their causes, prevention and rescue. The term entrapment is used when a grain bin worker becomes buried in the grain beyond the point of self-extraction. On the other hand, the term engulfment is used when a grain bin worker is completely buried or submerged beneath the surface of the grain.

Augers are very useful tools for handling and moving products on the farm. They save a great deal of time and physical labor. Unfortunately, injuries such as broken bones, cuts, amputations, electrocutions and even loss of life can occur from contact with parts of augers in operation or during transport. Becoming entangled in the auger, being trapped under a collapsed or overturned portable auger or being struck by a spinning elevation crank are just a few of the potential dangers of operating augers.

Questions?

Contact you local county Extension office