Economic Feasibility of Value-Added Production from Farmer's Market Surplus

Check out this guest post from Horticulture graduate student Morgan Gramlich as she shares results from a study she performed this past year with value-added products from farmer's markets!

My name is Morgan, and I am a graduate student in the Department of Horticulture at the University of Arkansas, Fayetteville. The purpose of this study was to determine if it is economically feasible to develop value-added products from farmers market surplus. Our goal was to use value added product development as a way to reduce food waste while increasing revenue for produce vendors. The data collected was used to determine if it was possible to develop products from the surplus produce at a small farmers market in Arkansas and to assess economic feasibility of these product development efforts. The farmers market studied was The Original Rogers Farmers Market located in Rogers, Arkansas.

Materials and Methods

The Original Rogers Farmers Market had about 20 vendors from Arkansas and Oklahoma, and 4-8 of these vendors sold produce in any given week. Produce was collected on market days (Wednesdays and Saturdays) for fourteen weeks (Jun 1-Sept 5) during the 2018 market season. At the end of every market, surplus produce was collected from vendors. Produce that could be prepped for long term (4-8 months) freezer storage (e.g., tomato, onion, peppers, etc.) was targeted rather than produce that was not suitable for processing and storage (e.g., lettuce, kale, leafy greens, etc.).

A walk-in refrigerator (2°C) was used to store surplus produce received, and a walk-in freezer (-10°C) was used to store pre-processed surplus. The recipe and product development for the surplus produce were completed at AFIC using typical kitchen-type equipment (blenders, food processors, and stove). The equipment used for large-scale product processing included an Electrolux Air-o-chill Flash Freezer (Model AOFP101CU), ULTRAVAC Vacuum Sealer (Model ULTRAVAC 500), Hobart Food Preparation Machine (Model FP400), an Urschel Comitrol Processor, 150 gallon (568 liters) stainless steel steam kettle (model N1991), and an Airtac Piston Filling Machine (Model SGF500-J). The produce was filled into 16 oz (473 mL) economy clear glass jars with 70-450 mm continuous thread gold-buff button top lids.

Produce Collected

We spent $2,460 to purchase 924 kg (2,036 lbs) of surplus produce from The Original Rogers Farmers Market during the 2018 market season. About 19% of the collected produce was donated, and 11% of the donated produce was used for the value-added production of tomato sauce.

Recipe Development

At the end of the farmers market season, the total amount of pre-processed and frozen produce was evaluated for a potential recipe based on what types of produce had been collected and the quantities. A recipe for tomato sauce was developed, although other possible products could have been a squash/zucchini flour or herb packets. The tomato sauce was the primary product developed for this project.

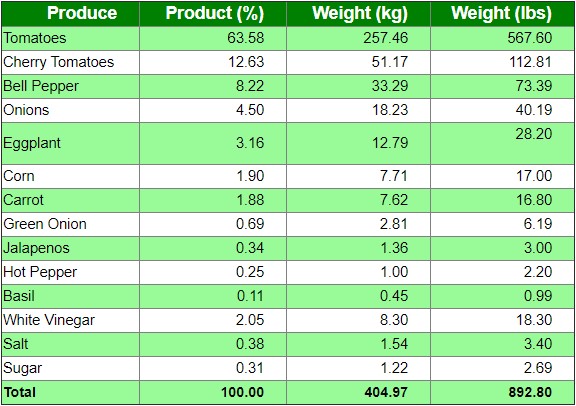

Recipe testing and development was initiated using the weights of each frozen produce item. The initial recipes were evaluated in small batches (9 kg or 20 lbs). Table 1 shows the final recipe used for sauce production that included tomatoes, cherry tomatoes, bell peppers, onions, green onions, eggplant, corn, carrots, jalapenos, and hot peppers with the addition of white vinegar, salt, sugar, and basil. The recipe was developed with the goal to have a flavorful, self-stable, and food-safe sauce. One of the key food safety goals was to have a final pH (acidity) of about 4.0 or less.

|

Table 1. Recipe for tomato sauce produced at the Arkansas Food Innovation Center, Fayetteville from farmers market surplus produce (2018).

|

Preparation and Production of Tomato Sauce

Tomato sauce production occurred after the recipe was finalized. The day before processing, the produce for production was removed from the freezer and weighed in the appropriate ratios according to the recipe. The produce was thawed at room temperature (21°C) for 24 hours.

The following day, the produce was chopped using the Hobart Food Preparation Machine. The chopped produce was collected in food grade buckets and then poured into the Urschel Comitrol Processor to reduce the produce to the consistency of a puree.

After cooking, the base of the kettle was connected to the Airtac Piston Filling Machine to hot fill two 16 oz jars, simultaneously. Once filled, the jars were sealed with lids by hand, inverted for two minutes to sterilize the inside of the lids, and then placed upright on a table to cool. After 24 hours, the jars were packaged into boxes. Within a month, the labels were applied to the jars. The final product was evaluated for pH, soluble solids (sugar level), and consistency. The sauce was submitted and received Process Authority Certification.

Economic Feasibility

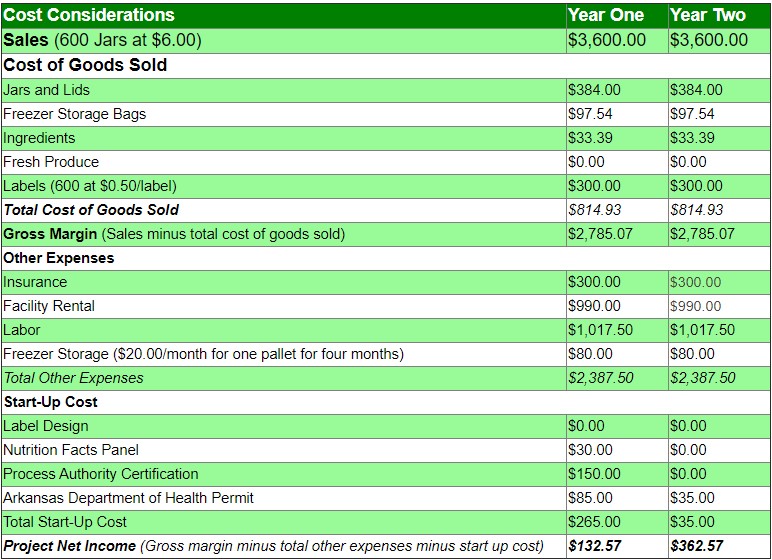

The economic feasibility of creating value added products from farmer’s market surplus was evaluated by analyzing the product development costs and potential revenues documented during the project. Table 2 shows a realistic cost analysis for implementing this project at a farmer’s market. The project could be implemented at a farmer’s market by the market manager, an individual hired by the farmers market, a group of vendors from the market, or an outside organization. Implementing this project at a farmer’s market may not be economically profitable using these estimates of cost, but is logistically feasible.

| Table 2. Anticipated economic feasibility for tomato sauce production at the Arkansas

Food Innovation Center, Fayetteville from farmers market surplus produce for the first

and second year after project implementation.

|

Sales. About 600 16 oz jars of tomato sauce were produced from surplus produce collected at the farmer’s market. The anticipated market value of the sauce was $3,600 ($6.00/jar).

Cost of Goods Sold. The jars and lids represent the wholesale price of purchasing 600 jars and lids. The freezer storage bags represent the wholesale price of purchasing storage bags for the produce (over half still remain). The ingredients represent the cost of purchasing additional ingredients (vinegar, salt, sugar, and dried basil) for production of the sauce. Fresh produce costs are entered as zero because product development uses produce that would otherwise be discarded. The labels are the price of purchasing product labels for the jars at $0.50 a label for 600 jars.

Other expenses. The insurance is the cost of food liability insurance that must be purchased yearly for clients of AFIC. The facility rental was calculated based on the hourly cost associated with the use of AFIC. The rental cost for the hours needed to implement this project included $840 for collection and pre-processing produce (2 hours at the end of every farmers market × 2 times a week × 14 weeks × $15.00/hour), $30 for preparation prior to production (2 hours × $15.00/hour), and $120 for day of production (8 hours × $15.00/hour). Labor cost was also calculated as $777 for one person spending 30-45 minutes collecting the produce at the end of the farmers market, driving to AFIC and pre-processing the produce (3 hours at the end of the market × 2 times a week × 14 weeks × $9.25/hour), $18.50 the day prior to production (2 hours × $9.25/hour), and $222 the day of production (3 people × 8 hours × $9.25/hour). The freezer storage was calculated based on the cost of storage for one pallet of product stored in the AFIC freezer at $20.00/month for four months (market season).

Startup Costs. The label design could be a cost consideration if a person is hired to professionally design a produce jar label and would cost $100.00- $300.00, but an individual could also design a label using computer software on a home computer. The nutritional facts panel represents the cost to develop a nutritional facts panel (one-time cost) that is required for the label. The process authority certification is the price associated to get the product certified with the Food and Drug Administration (one-time cost) for a product of this type. The Arkansas Department of Health permit is required for the production of a commercial food produce and has an initial cost of $85.00 and $35.00 every year after.

Projected Net Income. Under this model for the use of surplus produce from a farmer market to create a value-added product there would be an anticipated projected profit of $132.57 in the first year $362.57 in the second year.

Recommendations to Improve Feasibility

There are potential ways to improve cost and logistic feasibility of the use of farmers market surplus to create commercial food products. Some suggestions include:

- Use a different production facility with lower or no cost (church kitchen, school kitchen, restaurant, or co-op kitchen)

- Find student interns or volunteers to reduce labor costs

- Create a different product to reduce production costs (jams, jellies or dried produce)

- Engage a farmer’s market with vendors with varied produce

- Implement at a larger farmer’s market with more surplus produce potential

One of the key factors for success would be to engage a farmer’s market (manager and vendors) willing to implement unique methods to reduce overall produce surplus/waste to provide a locally made product from local ingredients. Overall, there are many ways this project could be made economically feasible to generate additional income for farmers market vendors or for farmers markets. Our project was able to demonstrate that surplus produce captured at a farmer’s market can be turned into a value-added product that would save this produce from otherwise going to waste.

For more information on this project, please visit:

https://www.uaex.uada.edu/media-resources/news/may2018/05-22-2018-Ark-Farmers-Market-Surplus.aspx

This project was funded by a Specialty Crop Block Grant from the Arkansas Agriculture Department, USDA (AM170100XXXXG030).