Crush It Arkansas! Winemaking

Grapevines (Vitis species) are one of the most widely-planted horticultural crops, and the United States plays a major role in the grape and wine industry. Within the United States, Arkansas has a long history of grape and wine production with grapes grown in Arkansas including mostly native species and hybrids (crosses of Vitis species). Many commercial winemakers started careers by experimenting with making wine at home or on a small scale. Regardless if wine is produced on a large or small scale, there are several key steps to making grapes into wine.

Harvesting

Wine can be made from many types of fruits including berry fruits (grapes, strawberries, blackberries, blueberries, etc.), tree fruits (peaches, apples, cherries, oranges, etc.), tropical fruits (pineapple, banana, mango, etc.), and other fruits (watermelons, elderberry, cranberry, etc.). However, grapes have basic components (water, sugar, and acids) and other flavors that produce good quality wines. Fruit for winemaking can be purchased directly from growers or at commercial markets. In addition, fruit juices or concentrates can be purchased for winemaking.

The focus of this article will be on making wine from varieties of grapevines that can be grown in Arkansas. For a list of grape varieties for Arkansas refer to the University of Arkansas System Division of Agriculture (UA System) factsheet, Small Fruit Cultivar Recommendations for Arkansas (McWhirt et al., 2021, https://www.uaex.uada.edu/publications/pdf/FSA-6130.pdf). While V. vinifera (old world species) are grown worldwide, the varieties that grow well in Arkansas and similar growing regions are typically native species, such as Concord (V. labrusca), muscadines (V. rotundifolia), and hybrids (crosses of Vitis species). In Arkansas, two Vitis hybrids are Vignoles (a white wine variety) and Chambourcin (a red wine variety) (Figure 1) (McWhirt et al., 2021) which we will use as examples of wine production.

How much fruit is needed to make a case of wine? One case of wine has 12 750 mL (25 oz) glass bottles which is about 9 L (2.4 gal) of wine. It takes about 1.5 kg (3.3 lbs) of grapes to make one bottle of wine. So, you need 18 kg (40 lbs) of fruit to make one case of wine. It typically takes more fruit for white wine production than red wine production. The amount of grapes needed will vary depending on the grape variety, winemaking procedure, and equipment used.

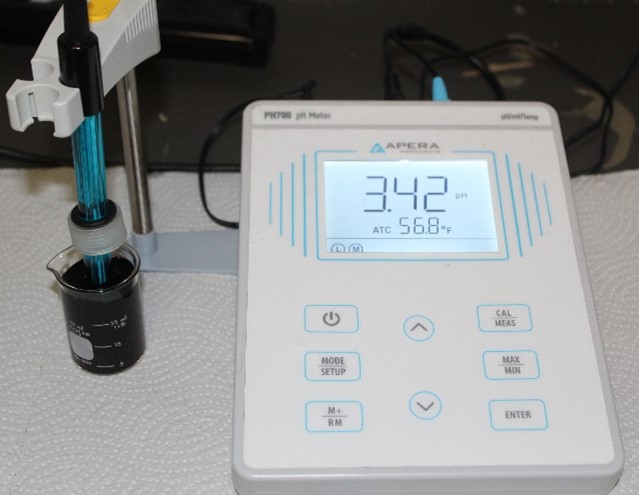

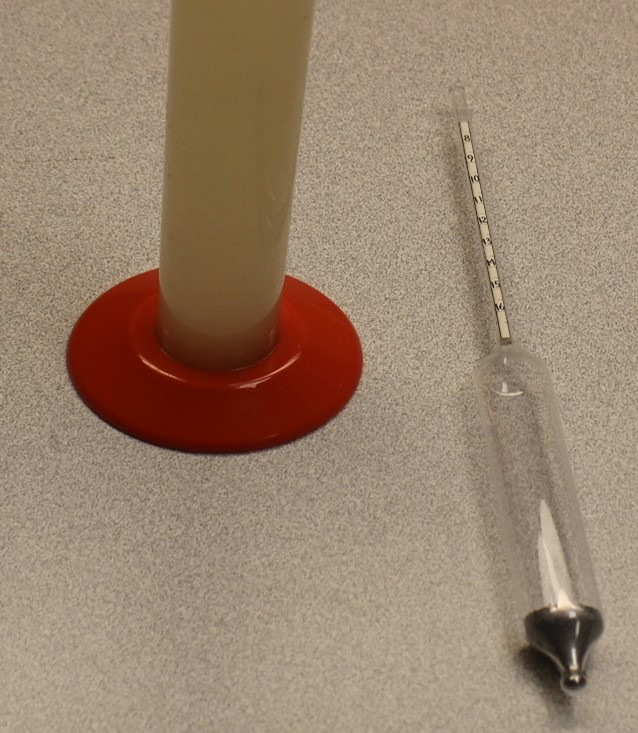

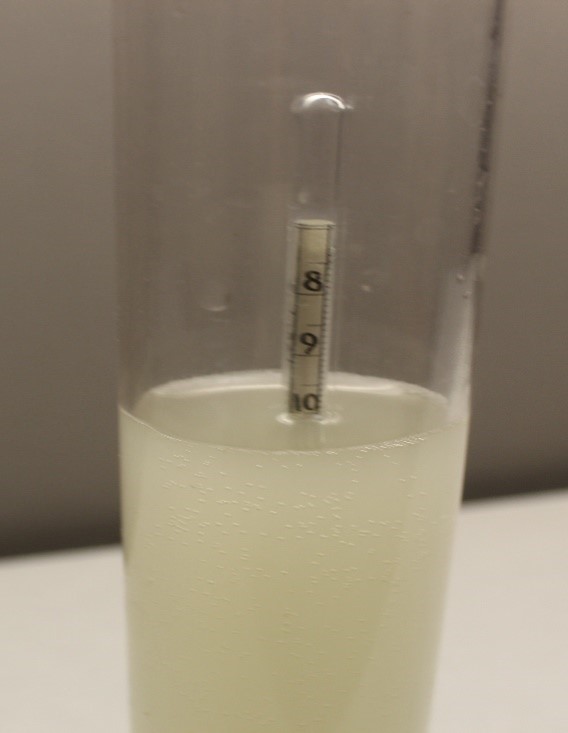

Whether you buy or harvest grapes for wine production, make sure that the quality of the fruit is good (no mold or rot) and that the grapes are mature or ripe. At harvest, the composition or chemistry of grapes should be 20-25% sugar (°Brix) and a pH of 3.2-3.5. This sugar content is important because about half of the sugar will be converted to ethanol by yeast during fermentation, and the lower pH is important for flavor, color stability, and avoiding microbial issues. The acidity (pH) in the juice of the grapes can be measured with a pH meter, and the sugars can be measured with a refractometer or hydrometer. In addition, a hydrometer can be used to measure the sugar levels during fermentation. These composition measuring devises can be purchased online or at local brewing or winemaking stores (Figure 2). It is possible to adjust the sugar and acidity of the juice or must (seeds, skins, pulp, and juice after crushing) after harvest, if needed. For reference, 1°Brix is equivalent to 1 g (0.03 oz) of sugar in 100 g (3.5 oz) of solution. The pH is a scale from 0 to 14 used to describe the acidity or basicity of a solution, with 7 being neutral. For example, a pH of 3 is ten times more acidic than a pH of 4, so it is important to understand that small changes in pH represent larger changes in acidity.

Figure 2. pH meter (top left), using a refractometer to measure sugars (top right), using a hydrometer to measure sugars in a juice (bottom left and right).

To maintain quality during wine production, it is important to sanitize everything that contacts the grapes, must, juice, or wine by thoroughly cleaning with hot water. After washing, all equipment should be thoroughly dried to prevent microorganisms such as yeast, bacteria, and mold, from growing and possibly contaminating the final wine. When harvesting grapes, it is best to harvest while it is cool outside for overall fruit quality, therefore, early morning harvest is recommended. Once grapes are obtained, they should be processed immediately. If grapes are not processed quickly after harvest, they should be chilled in a cooler or refrigerator at 2-4°C (35-40°F) for 24-48 hours before processing to reduce their temperature from the field. Another method to chill the grapes in large harvest bins would be to add dry ice (solid form of carbon dioxide) to the bins.

Destemming and Crushing

After harvesting, the red or white grapes should be destemmed and crushed. Grape stems are typically removed before crushing because they can impart bitter flavors. Crushing grapes leads to better extraction of juice (higher yield) and better maceration of skins (better color and flavor extraction). A crusher/destemmer is a machine that crushes grapes by passing them through a set of rollers in addition to removing the stems. While equipment can be purchased for crushing/destemming (Figure 3), there are other options for home winemakers. To destem or crush grapes at home, place a plastic milk crate in a plastic bin, place the grapes on the crate, then smash the clusters through the holes in the crate. A “wash-board” scrubbing motion is recommended to thoroughly crush the grapes (Figure 4). The same concept could be used with a baking cooling grid/rack, a window screen, or colander.

Figure 3. Top view (left), side view (center), and back view (right) of a small-scale commercial grape crusher-destemmer.

Figure 4. Crushing-destemming grapes into plastic bins using a plastic milk crate (left) or stainless steel baking cooling grid/rack (right).

During winemaking, chemicals can be used to maintain the quality of the wine. For example, 30 mg/L (0.004 oz/gal) of sulfites or sulfur dioxide (SO2) can be added to the must during crushing to prevent spoilage (caused by yeast, bacteria, or mold) and to control oxidation (browning). Potassium metabisulfite (KBMS) contains sulfites and can be purchased online or at winemaking/brewing stores. To determine the amount of KMBS to use, the actual amount of sulfite in the KMBS needs to be calculated. For example, if you need to have 30 mg/L (0.004 oz/gal) sulfite to add to the juice/must, and the KMBS contains 57.6% sulfur dioxide, the amount of KMBS needed is 52.08 mg/L (0.007 oz/gal). It is important to note that sulfites use is pH dependent, meaning that less sulfites are needed if the pH of the juice/must/wine are lower. For more information on using sulfites and determining the amount of sulfite for wine production based on pH visit https://extension.psu.edu/sulfur-dioxide-management (Gardner, 2016).

Pressing

Pressing is done to extract more juice/wine from the grapes/must. White and red wine grapes are typically pressed at different stages. After crushing, white grapes are pressed to extract more juice that is not released from the grapes. For red wine, crushed red grapes should be fermented on the skins, then pressed. Again, various types and sizes of presses can be purchased for winemaking (Figure 5), but the grapes can also be pressed by hand. Multiple pressing cycles can extract more juice/wine. Pressing with a press offers low damage to skins and seeds (minimum extraction of bitter/astringent compounds). A milk crate, strainer, or colander can be used to press grapes by hand (Figure 6) but are not as effective as commercial-grade presses. After pressing, juice from white grapes should be cold settled by placing the container of juice in the refrigerator, chilling the juice overnight, and racking the juice from the lees (sediment, mostly grape berry particles) at the bottom of the container.

Figure 5. Loading a small-scale commercial vertical grape bladder press (left), pressing the grapes (center), and grape skins/pomace after pressing (right).

Figure 6. Pressing grapes with plastic milk crate (left), strainer (center), or colander (right).

Fermentation

Commercial wines are fermented in stainless steel tanks. Home wines can also be fermented in stainless steel but are more frequently fermented in glass carboys or large plastic (food grade polyethylene) buckets. In general, glass is superior to plastic for wine fermentation because glass is inert, transparent, and easy to clean, but it is expensive, heavy, and has smaller volumes (Jackson, 2008). Plastic is inert, light weight, less expensive, has larger capacity, but is porous and opaque. Oxygen control is important in winemaking because yeast need oxygen during initial fermentation, but then oxygen must be minimized in the later stages of fermentation. It is better to use glass containers in the later stages of home wine production because they are not as permeable as plastic containers and have a smaller headspace at the top of the container. Thus, multiple sizes of containers are suggested for wine production (Figure 7).

Figure 7. Various sizes from 1.9 L (0.5 gal) to 23 L (6 gal) of glass carboys with fermentation locks used for winemaking.

After pressing, the sugar and acidity of the juice should be measured. Sucrose (table sugar) can be added the juice/must to increase the sugar level. The pH of the juice/must can be adjusted by the addition of tartaric acid (the main acid in grapes). In general, 1 g/L (0.13 oz/gal) of tartaric acid will decrease the pH by 0.1. After adjusting the sugar and acidity, the commercial winemaking yeast should be added to the juice. Yeast need oxygen and nutrients (nitrogen and minerals) to survive during a fermentation, so nutrients can be purchased and added to avoid problems with fermentation.

Fermentation is the conversion of sugar (from the grapes) into ethanol (alcohol) and carbon dioxide. Yeast, a single-celled microorganism in the fungus kingdom, is naturally capable of performing this process. Successful fermentation should (1) ferment to dryness (no remaining sugar), (2) produce minimum undesired byproducts, (3) maximize natural aromas and flavors of fruit, and (4) enhance the unique character of the wine. Commercial yeast for winemaking can be purchased in both liquid and dry forms. Inactive dry yeast is rehydrated prior to use and is typically easier to use for home winemaking (Figure 8). The method to rehydrate yeast and the amount of yeast to add to the juice/must will be specified by the manufacturer of the yeast. Different strains of yeast can impact the aroma and flavor of the wine.

Figure 8. Inactive dry yeast for wine production.

Keep in mind that temperature influences the fermentation rate of the wine. Wine should be fermented slowly at lower temperatures. White wines are fermented at 13-16°C (55-60°F), while red wines are fermented at 24-29°C (75-85°F) (Dharmadhikari and Wilker, 2001; Ough, 1992; Taylor and Vine, 1968, Zoecklin et al., 1995). When making white wines the juice should be placed in a closed container with fermentation locks (Figure 9). Fermentation locks should be vented to allow the release of carbon dioxide and have a liquid trap with a sulfite solution prevents air/insects from entering the container. Early in the fermentation, you will want to leave more headspace in the top of the because the fermentation will be very active.

Figure 9. Fermentation lock containing a sulfite solution inserted in a cork on a carboy of wine.

After crushing, the must of red wine grapes are placed in containers, and yeast is added to ferment on the skins during alcoholic fermentation (Figure 10). Leaving containers of must open would make them susceptible to insect pests and microorganisms. Therefore, for home wine production, we recommend that red wine grape must be placed in a clean plastic container lined with a food-grade plastic bag and loosely taped closed so carbon dioxide can escape during fermentation (Figure 10). During this fermentation, a cap of skins will float to the top, and this cap should be punched down from outside the bag 3-4 times per day. The purpose of punching down the skins is to extract more pigments (which give color to the wine), mix the wine to ensure even temperature and yeast distribution, and reduce bacterial growth (the alcohol produced by the yeast will reduce or eliminate most undesirable microorganisms). The bag will also fill with carbon dioxide but will be released during this punch down. The must will remain on the skins for a few days, but once alcoholic fermentation is near completion, the red wine must should be pressed.

Figure 10. Using a lined plastic container for red wine must fermentation (left) and punching down the cap of the must during fermentation (right).

The fermentation is near complete when there are less than 2 g/L (0.2%) residual sugars (as measured with a hydrometer). Fermentation of the remaining sugars continues for several months depending on the type of grape and the style of the wine made. During these months, unwanted “secondary” fermentation can occur. Therefore, the wine should be racked, tasted, measured, and smelled often to detect any potential issues. Listed below are four common fermentation problems and potential solutions (Jackson, 2008; Zoecklein et al., 1995).

- Vinegar bacteria (Acetobacter) convert alcohol to acetic acid (vinegar) and can quickly ruin a wine. The best prevention against vinegar bacteria is good sanitation but if low amounts of vinegar are detected, the affected wine can be blended with other wines to reduce the impact.

- Wild yeasts (Brettanomyces) convert sugars into acids and off-flavors. The best prevention to prevent wild yeast contamination is sanitation and use of sulfites.

- Stuck fermentations is when active fermentation stops before all the sugar is consumed, and the wine is dry. The wine could begin fermenting again in the bottle, and the bottle could explode or wild yeast/bacteria could use this sugar and produce off-flavors. Fermentations usually become stuck when there is a lack of yeast nutrients or incorrect fermentation temperature. The best prevention for stuck fermentations is to rehydrate yeast properly, add yeast nutrients, rack ofter, and ferment at the correct temperature.

- Oxidation is when ethanol is oxidized to acetaldehyde (cooked apple/rotten aromas), and the oxidative off-flavors/colors are the most common defects in homemade wines. Prevention of oxidation is to minimize oxygen exposure during wine production and bottling and add sulfites at crush and after fermentation. During the later stages of fermentation or after fermentation is completed, the wines should be racked into a container with no head space.

Clarification and Stabilization

It is important to clarify and stabilize the wines prior to bottling. During and after fermentation wine contains dead yeast cells, tartrate crystals, small fragments of grape tissue, and other debris that can make wine appear cloudy. Ways to clarify and stabilize wine include cold stabilization, racking, fining, filtering, and chemical preservatives.

During wine fermentation tartaric acid can form tartrate crystals which will eventually precipitate and settle to the bottom. When white wine is chilled, some tartrates can precipitate. Therefore, white wines should be chilled at -2.8°C (27°F) for several months prior to bottling for cold stabilization. Red wines are not typically cold stabilized prior to bottling.

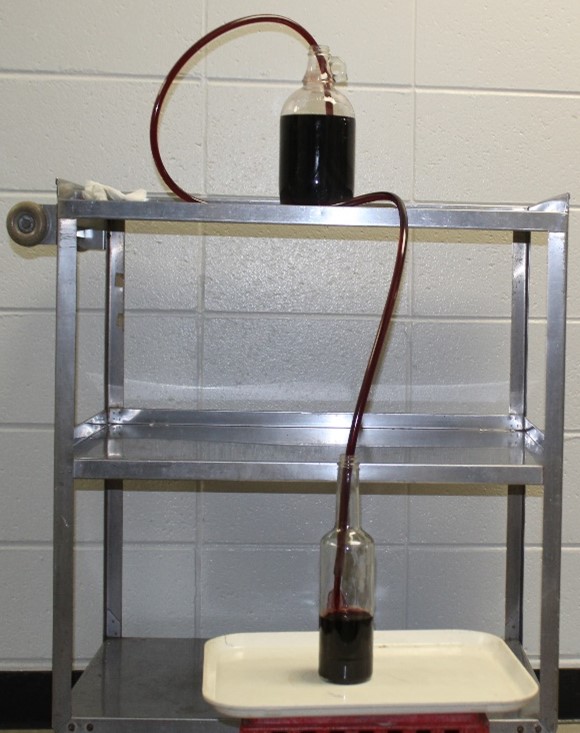

Racking is the separation of juice or wine from the sediment (lees). This should be done several times during fermentation. Particles will settle to the bottom via gravity, and the juice or wine can be siphoned or decanted into a new container, leaving the sediment behind (Figure 11). A good racking regime can help ensure a clear, stable wine.

Figure 11. Lees (sediment) in a carboy before racking (left) and process of racking wine from a large carboy to a smaller carboy (right).

Fining agents are various wine additives that can enhance color, clarity, taste, and stability while reducing the concentration of or removing undesirable components. Fining agents can help settle particles which are still suspended in the wine, however, excess fining can strip aroma, color, and flavor of wines. Examples of fining agents include bentonite (a fine clay of aluminum silicate), gelatin (made from animal bone and skin), or albumin (egg protein) (Zoecklein et al., 1995).

Filtering wine before bottling is not necessary if the winemaker has done a good job of racking and management during wine production, resulting in a clear, sound wine. Filtering is the process where the wine is passed through screens or filters that remove unwanted materials (including microorganisms) from the wine. The filters can vary in the size so that rough filtering and be done to remove larger materials or sterile filtering can be done to remove all microorganisms. Various types of filters and filtering systems can be purchased for home winemaking.

Chemical preservatives can be used to sterilize (death of all microorganisms) wine but can affect color and flavor. There are two chemical preservatives typically used in wine production: sulfur dioxide (sulfites) and sorbic acid (sorbate). Sulfites are effective against spoilage yeast and bacteria and react with dissolved oxygen to prevent oxidation reactions thus inhibiting browning. However, if too much sulfites are used it can bleach the color of the wine and impart undesirable odors similar to cooked eggs or burnt matches. As previously mentioned, the recommended dosage at crush is 30 mg/L (0.004 oz/gal), and 60 mg/L (0.008 oz/gal) at the end of fermentation. It is important to remember that the free SO2 level (sulfites that are not bound to other chemicals and can react with substances) is dependent on the pH of the wine (Gardner, 2016, https://extension.psu.edu/sulfur-dioxide-management ). Sometimes, are made in a sweeter style at bottling, thus either the fermentation is halted to have residual sugar or sugar is added back to the wine. In this case, sorbate is also added to inhibit yeast and bacteria growth. It is typically added to wines with residual sugar at the time of bottling to prevent fermentation from starting in the bottle. A fermentation in the bottle would result in carbon dioxide release that could cause the cap come off, the cork to push out, or the bottle could explode. The recommended dosage of sorbate is 264 mg/L (0.04 oz/gal). Sorbate is typically purchased and added as potassium sorbate. The addition of sorbate to wine can form ethyl sorbate, a pineapple aroma, in wines.

Bottling and Aging

When desired, wines can be aged in oak barrels, in tanks with oak adjuncts (staves or chips), or in the bottle. Oak barrels are traditionally white oak (French oak or American oak) that gives wine a spicy, woody, vanilla flavor, typically desirable in most red wines and some whites. Oak barrels are expensive and heavy and often impractical for use by home winemakers. After 4-5 years, an oak barrel loses aroma and flavors for wine production so can no longer be used. Wood is also difficult to sanitize and is easily contaminated with undesirable yeast and bacteria. Oak chips or oak staves are more practical for home winemakers because they can be added directly to the wine. Oak chips can be suspended in a mesh bag, and oak staves can be directly added to the wine. The amount or oak staves or chips depends on the style of the wine and preference but begin with the manufacturer’s recommendations if uncertain.

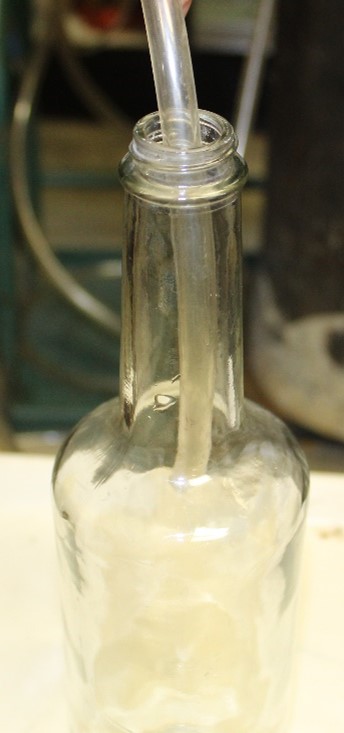

When satisfied with the final wine’s characteristics, the next step is bottling. Bottles can be filled through gravity siphoning with a piece of tubing or hose (like used for racking). Screw-cap bottles are recommended for ease-of-use rather than cork closures (Figure 12). Oxygen control is crucial at this stage, so be sure to minimize splashing and bubbling when filling the bottles. If possible, flush oxygen from the bottle by using liquid nitrogen or dry ice (sparging) (Figure 12). After the wine is bottled, it can be consumed as “young” wine or stored for aging. During aging, oxygen is no longer available, so new reactions begin to occur. Red wines are typically aged for extended periods of time (>1 year) though some white wines are aged for extended periods.

Figure 12. Screw cap and wine bottle (left), sparging a wine bottle with nitrogen gas (center), and bottling wine with gravity siphoning (right).

Winemaking at home is an exciting new skill to try! If you have any questions, please feel free to contact Dr. Renee Threlfall, Research Scientist, UA System (rthrelf@uark.edu, 479-575-4677). Cheers!

References

- Dharmadhikari, M.R., and K.L. Wilker. 2001. Micro Vinification: A Practical Guide to Small-scale Wine Production. Missouri State Fruit Experiment Station, Mountain Grove, MO.

- Gardner, D. 2016. Sulfur Dioxide Management, Penn State Extension, https://extension.psu.edu/sulfur-dioxide-management

- Jackson, R.S. 2008. Wine Science: Principles and Applications. Academic Press. Massachusetts.

- McWhirt, A., J. Clark, M. Worthington, R.T. Threlfall, and M. Bertucci. 2021. Small Fruit Cultivar Recommendations for Arkansas. University of Arkansas System Division of Agriculture Cooperative Extension Service. FSA6130. https://www.uaex.uada.edu/publications/pdf/FSA-6130.pdf

- Ough, C.S. 1992. Winemaking Basics. The Haworth Press, Inc., Binghamton, NY

- Taylor, W.S., and Vine, R.P. 1968. Home Winemaker’s Handbook. Harper and Row, New York.

- Zoecklein, B.W., K.C. Fugelsang, B.H. Gump, and F.S. Nury. 1995. Wine Analysis and Production. Kluwer Academic/Plenum Publishers, NY.